Compact, fully automatic film processor.

The Minilab for your desktop.

Made in Germany.

THE FILMOMAT.

what is the filmomat?

The Filmomat is a fully automatic table-top film processor. It can process anything from 35mm up to 5x7" - and even Super-8 or 16mm motion picture films. The machine can run any process from b/w negative, E6, up to ECN-2. Just fill in the chemistry and press the button, the machine will do the rest. The whole process sequence including rinsing steps, bath changes and temperature control is carried out completely automatic. Every machine is hand-crafted in my workshop in Munich, and undergoes individual testing and quality control before shipping.

Overview

The Filmomat is made out of laser-engraved acrylic glass. The process chemistry (500mL for each step) is stored in three acrylic tubes, which are surrounded by a waterbath. A powerful 650W heater brings the waterbath to the correct temperature. Throughout the whole developing process, the waterbath is kept at the desired temperature with 0.1° accuracy. Two digital temperature sensors inside the waterbath and the chemistry tanks ensure accurate temperature measurement.

Separated from the heated waterbath is an additional 7-liter containing compartment, which is used for rinsing steps. This compartment is not temperature controlled. No water connection is required. Used water is drained through a waste-water-exit, which can be connected to a discharge or a collection tank by a hose. Used chemicals are always pumped back into their storage tubes. Once you are finished, you can drain them by the drain valves on the right of the machine.

Rotational development

The Filmomat system is based on rotational development. Up to 4 rolls of 135 or 120 can be loaded into a big tank, which is oriented horizontally in the Filmomat. A small motor inside the tank rotates the film spirals inside. The tank itself remains steady. Rotation direction is inverted every 15sec, ensuring proper agitation of the chemistry. Rotation speed can be adjusted by the user.

One tank - all possibilities

There is just one processing tank which handles every format from 35mm up to 5x7”. Professional flm spirals of the Jobo 2500 system are used to hold the film. This allows you to process 135, 120 and 4x5” all together in various combinations. Using the additional motion picture tank system you can even process Super-8 and 16mm motion picture film fully automatically with the Filmomat!

Great efficiency

You can process 4 rolls of 135/120, 6 sheets of 4x5” or two sheets of 5x7” (film or paper) per run. Only 500mL of chemistry are required for the machine, making it very economic towards chemistry use. Even two rolls of Super-8 (30m!) can be processed with only 500mL chemistry.

For professional and home use

The Filmomat is designed for both amateurs and professionals. The variety of different film formats and possible processes makes the Filmomat one of the most versatile film processors on the market. With 8 years of experience in the field, the Filmomat has proven to be a reliable and powerful system. Both photographers and small commercial labs all over the world are using the machine for successful film processing.

how it works

The heart of the system is a large, cylindrical processing tank. It is connected to the Filmomat in horizontal orientation by a strong quick connector. The connector holds the tank in place and also acts as an in- and outlet for the chemistry. Film is loaded on spirals of the professional Jobo 2500 system. These spirals are available for 135, 120, 4x5” and 5x7” - enabling you to process all formats in just one tank and in any combination you like. With the additional motion picture processing tank you can even process 15m Super-8 and 16mm film!

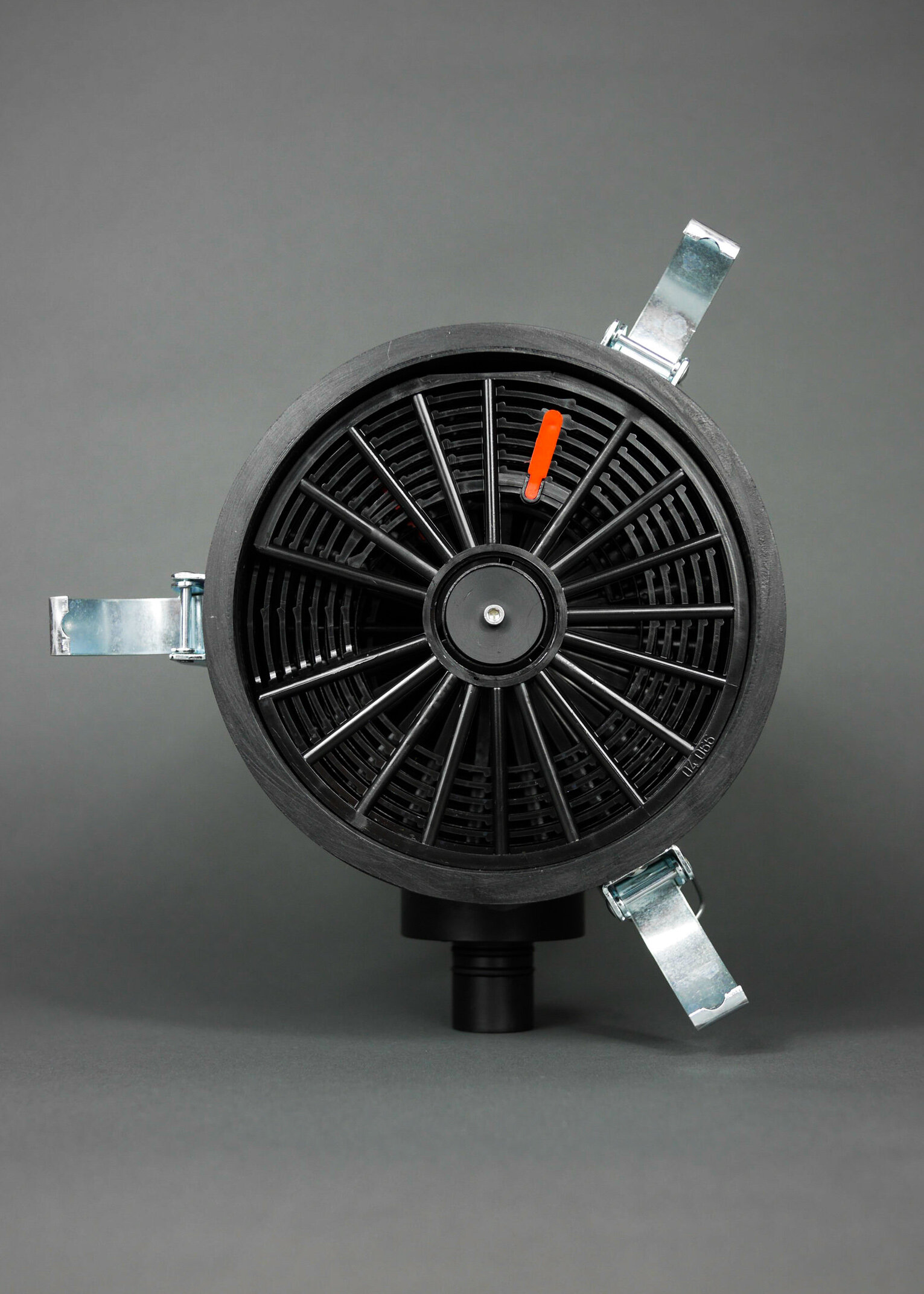

The cap of the tank contains a motor, which rotates the spirals inside the tank. The processing tank itself remains steady all the time, only the spirals inside the tank are moving (adjustable between 20 and 50rpm). Every 15sec, the direction of the rotation is inverted to ensure proper agitation. Due to the quiet motor, the Filmomat remains almost noiseless during operation.

All processes are controlled by a microprocessor, ensuring highest reproducibility and accuracy. Both timing and temperature are regulated fully automatically.

You can process 4 rolls of 120 or 135 at a time. Combinations of both are also possible, for example 2x135 and 2x120 in one run! Film spirals are available all the way up to 5x7”. The additional motion picture tank allows processing of 2x15m Super-8 or 1x15m 16mm film.